Why Robo Assistant is the Future of Smart Execution

Bridge the gap between AI and physical systems with an automation solution that adapts to any industry.

We understand that adopting a new system — especially one that touches your core processes — can feel risky. But continuing to rely on legacy stacks held together by patches, workarounds, and rising costs is often far riskier in the long run. That’s why Robo Assistant isn’t here to replace everything overnight — it’s built to co-exist with your current systems, augment your capabilities, and transition at your pace. With high personalization, expert support, and modular architecture, you can start small — and scale as confidence grows. Innovation doesn’t have to be disruptive. It can be strategic, gradual, and fully under your control.

Explore Our Ecosystem

AI-Driven Device Control & Coordination

Seamless Device Management

What It Does:

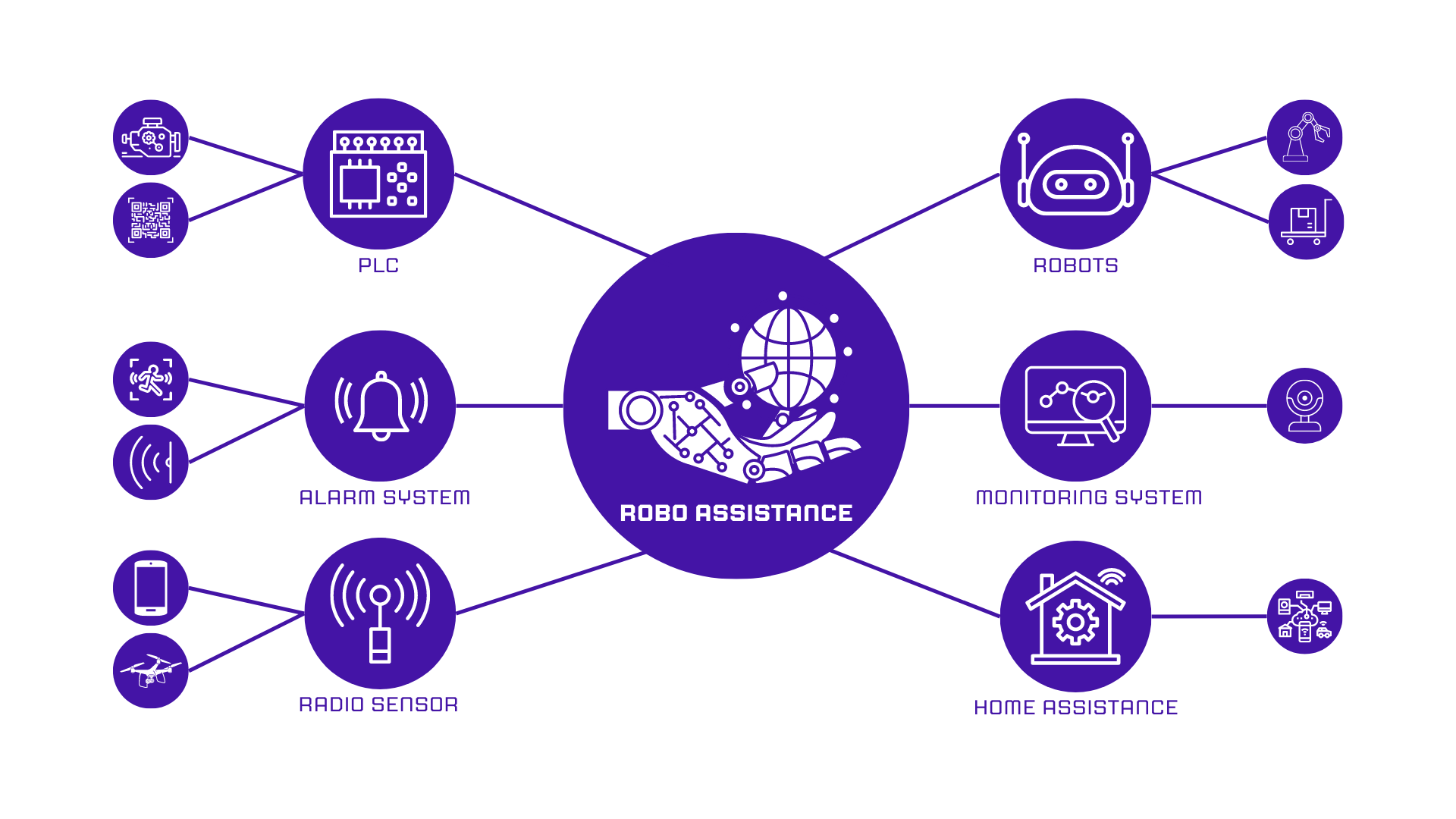

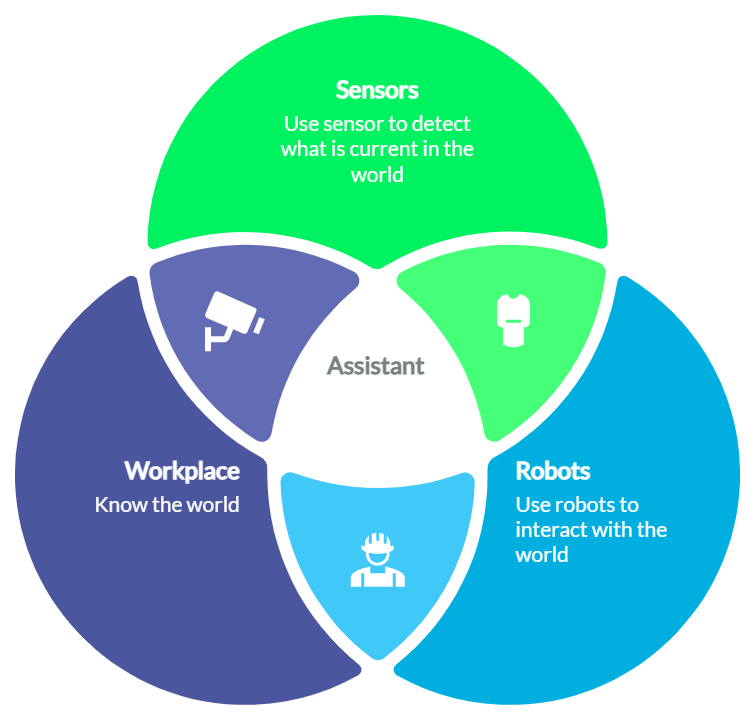

Controls robots, sensors, and execution devices while optimizing their interactions.

🚀 Why It Matters:

- ✅ AI-based device control & command execution.

- ✅ Efficient interaction between multiple device types.

- ✅ Dynamic adaptation to task requirements.

🔗 How It Works:

- 1️⃣ AI assigns tasks to relevant devices.

- 2️⃣ Devices execute actions based on standardized commands.

- 3️⃣ System monitors execution & adjusts if needed.

Intelligent Sensor Monitoring & Data Fusion

Unified Data for Smarter Decisions

What It Does:

Aggregates sensor data, detects patterns, and optimizes system responses.

🚀 Why It Matters:

- ✅ Real-time environmental awareness.

- ✅ AI-powered data fusion for better insights.

- ✅ Seamless integration with machine control.

🔗 How It Works:

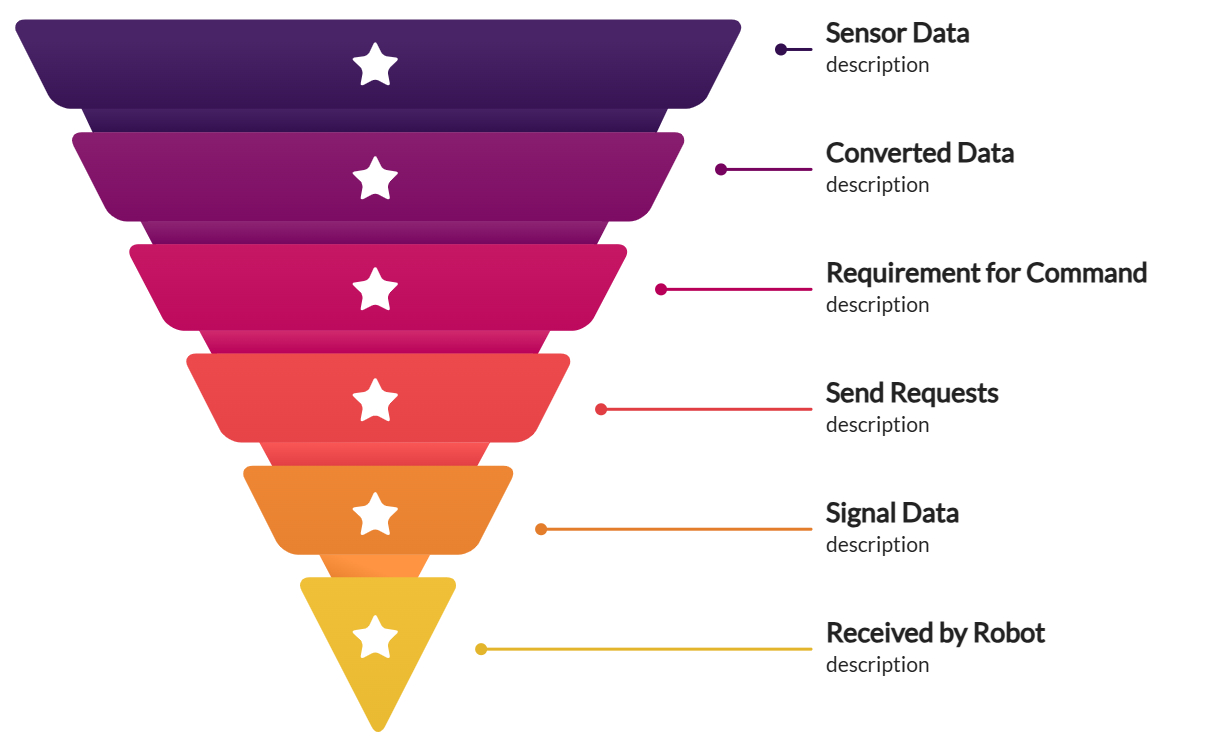

- 1️⃣ Sensors collect data in real time.

- 2️⃣ AI aggregates and processes information.

- 3️⃣ The system triggers automated responses based on insights.

Automatic Device Configuration

AI-Enabled Self-Configuration

What It Does:

Detects new devices and configures them based on existing drivers.

🚀 Why It Matters:

- ✅ Reduces setup time for new devices.

- ✅ Ensures compatibility across the ecosystem.

- ✅ Enhances scalability with minimal manual intervention.

🔗 How It Works:

- 1️⃣ The system detects a new device.

- 2️⃣ AI matches it with existing drivers.

- 3️⃣ Configuration is applied automatically.

Orchestrating Multiple Devices

Coordinated Execution at Scale

What It Does:

Ensures smooth collaboration between various devices in a production setting.

🚀 Why It Matters:

- ✅ Optimizes workflows across machines and robots.

- ✅ AI-driven task assignment for efficiency.

- ✅ Minimizes delays in process execution.

🔗 How It Works:

- 1️⃣ Tasks are distributed based on device availability.

- 2️⃣ AI synchronizes operations between devices.

- 3️⃣ Execution is monitored and adjusted dynamically.

Flexible Communication Methods

Connectivity Without Limits

What It Does:

Supports diverse communication standards for device interactions.

🚀 Why It Matters:

- ✅ Enables hybrid communication approaches.

- ✅ Supports WiFi, Ethernet, Bluetooth, 5G, and more.

- ✅ Ensures reliable and efficient device connections.

🔗 How It Works:

- 1️⃣ Devices choose the best communication method.

- 2️⃣ AI optimizes network usage and latency.

- 3️⃣ Data is exchanged seamlessly between devices.

Task Execution Verification

Ensuring Reliable Task Completion

What It Does:

Validates if devices correctly execute assigned commands before proceeding.

🚀 Why It Matters:

- ✅ Prevents errors and ensures task accuracy.

- ✅ AI-driven quality control.

- ✅ Eliminates manual verification steps.

🔗 How It Works:

- 1️⃣ AI checks task completion status.

- 2️⃣ If a failure occurs, AI initiates corrective actions.

- 3️⃣ The system proceeds only after successful validation.

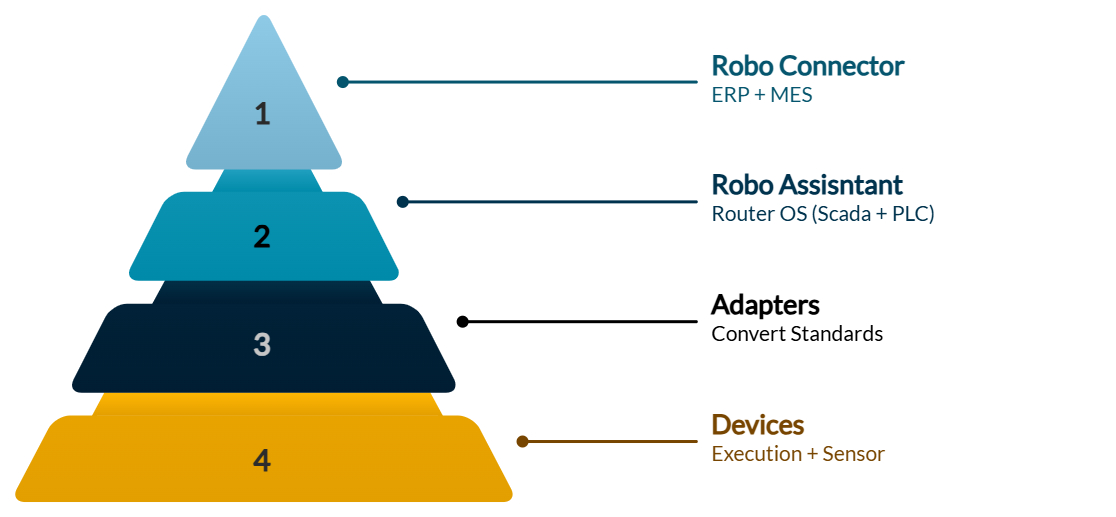

The Automation Pyramid defines different levels of industrial automation, from enterprise planning to machine control. Robo Connector operates at the Enterprise Resource Planning (ERP) and Manufacturing Execution System (MES) levels, handling business process orchestration, production planning, and enterprise-wide automation. Meanwhile, Robo Assistant functions at the Supervisory Control and Data Acquisition (SCADA) and Programmable Logic Controller (PLC) levels, directly managing devices, monitoring real-time operations, and executing precise control over production processes. To bridge the gap between various hardware and communication protocols, additional Adapters convert Robo Assistant's standard into specific device formats, ensuring seamless integration within both the data layer and communication layer. This architecture enables full-stack automation, from high-level business decision-making to low-level machine execution.

Robo Assistant – The Ultimate Industrial Orchestrator

Transform your manufacturing and logistics operations with AI-driven orchestration, real-time monitoring, and seamless device coordination.

Book a Demo Now

Book a Demo Now

The Problem

Traditional ERP/MES/WMS systems struggle to integrate multiple devices, automate workflows, and ensure real-time monitoring. Manual oversight leads to inefficiencies and delays.

How Robo Assistant Works

Execution & Coordination

Converts procedure steps into commands and orchestrates device actions efficiently.

Automation & Monitoring

Merges sensor data, tracks device movement, and ensures real-time monitoring.

AI-Driven Auto-Configuration

Automatically configures new devices based on installed drivers.

Seamless Communication

Supports multiple communication standards like WiFi, 5G, Ethernet, SDR.

Where It’s Used

Manufacturing & Production

Automates production lines and ensures devices work in sync.

Warehouse & Logistics

Optimizes warehouse automation and real-time inventory tracking.

Smart Factories (Industry 4.0)

Enables AI-driven machine-to-machine communication for full automation.

Designed to integrate natively with Robo Assistant, this next-generation robotic arm offers high flexibility, real-time coordination, and unmatched modularity for industrial environments.

🔩 Core Performance Specs

- Payload: Up to 30 kg

- Reach: ~1.2–1.5 meters (depending on configuration)

- Repeatability: ±0.05 mm

- Max Speed: ~1 m/s (joint-level); task-optimized with AI

- Degrees of Freedom: 6 or 7 DoF (modular)

- Weight: ~50–75 kg (depending on payload config)

🧠 Integrated Smart Features (via Robo Assistant)

- Auto-reconfiguration: Robotic arms can couple to boost payload or precision

- Context-Aware Operation: Robo Assistant generates task logic & motion plans dynamically

- Fleet Intelligence: Coordinate multiple arms, AGVs, sensors in real-time

- Sensor Fusion: Load cells, encoders, cameras supported

- Wireless Connectivity: Central router or edge device for command & data sync

🔧 Interchangeable Tools

- 🔹 Universal Parallel Gripper (Standard)

- 🔹 High-Precision Cutter (for light materials, wiring)

- 🔹 Touch/Proximity Sensor Tool (inspection, detection)

- 🔹 Optional custom end effectors (CNC, welding, etc.)

💡 Designed For

- Factory automation lines (modular setups)

- Warehouse handling (box transfer, smart picking)

- Laboratory & cleanroom environments

- Flexible, cost-optimized pilot projects

💲 Estimated Cost (Prototype Stage)

$5,000 – $9,000 per full unit (basic model, production batch cost TBD)

⚙️ Designed for industrial use. Seamlessly integrates with Robo Assistant for intelligent, flexible, and modular automation.

Pre-orders available soon. Contact us for early partnership opportunities.

See Robo Assistant in Action

Experience the future of automation with AI-powered orchestration.

Book a Demo Now